Communication systems for industrial automation still mainly rely on cables (fieldbusses), as such systems provide strong guarantees regarding low latency and high reliability, which are both necessary to realize mission- or safety-critical applications in the context of industrial processes. However, wireless technologies may lead to an increased flexibility in industrial automation and furthermore reduce costs in deployment and maintenance of communications.

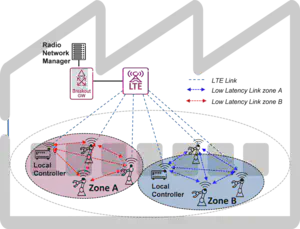

A precondition for bringing wireless technologies to industrial automation, is to ensure similar communication guarantees as the hitherto existing wired solutions, while also exploiting the advantages of wireless systems. The KoI-Project (Koordinierte Industriekommunikation) aims at developing a communication system for industrial automation, which enables reliable communication within local automation cells and the coordination of these cells via LTE. It is a joint project between COMSYS (RWTH Aachen University), WZL (RWTH Aachen University), Ericsson, HHI (Fraunhofer), University of Paderborn (UPB), WiseSense GmbH and Weiss Robotics GmbH. The focus of COMSYS lies on designing and implementing a reliable data link layer for local production cells and further to develop a cross-layer framework for the resource coordination of multiple communication cells.

More information on this project and our project partners can be found on www.koi-projekt.de.

Partners

- Laboratory for Machine Tools and Production Engineering (WZL, RWTH Aachen University)

- Ericsson GmbH

- Universität Paderborn

- Fraunhofer Heinrich Hertz Institute (HHI)

- WiseSense GmbH

- Weiss Robotics GmbH & Co.KG